Special Purpose Sealers

Applications

Unique Bag Shapes and Materials: Sealing non-standard pouches, bags, or materials that require specific handling or sealing techniques.

Medical and Pharmaceutical Packaging: Creating tamper-evident seals for sterile packaging or integrating features like gas flushing for oxygen-sensitive products.

Food Packaging: Sealing packages with complex shapes or incorporating features like easy-peel functionality.

Industrial Applications:** Sealing heavy-duty materials, bags containing hazardous materials, or integrating features like dust-free sealing environments.

Key Features

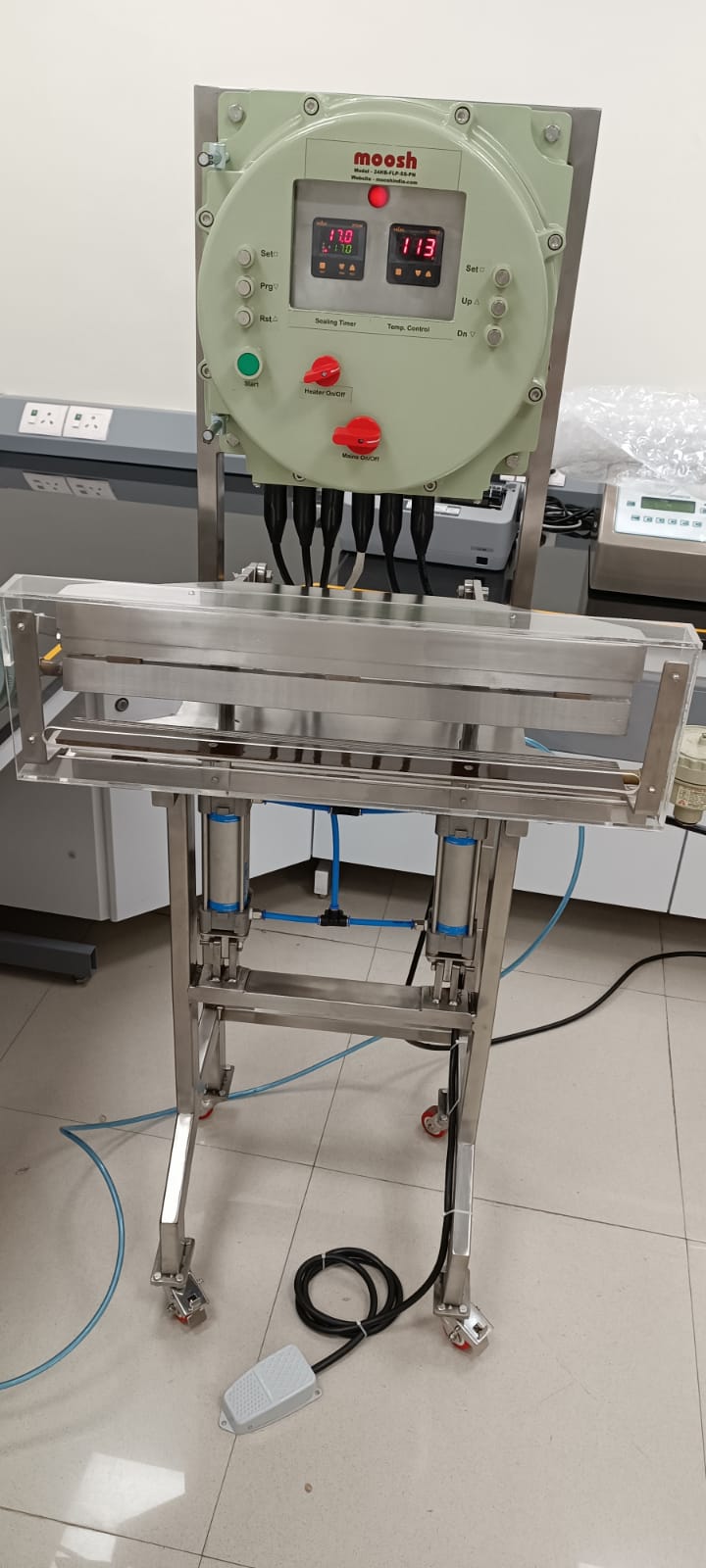

Sealing Mechanism: Choose from impulse sealers, hot bar sealers, or radio frequency (RF) sealers depending on the material and desired seal strength.

Sealing Width and Length: Sealing bars or electrodes can be customized to perfectly match the dimensions of your specific bags or pouches.

Automation Level: Integrate foot pedal operation, conveyor belt feeding systems, or full automation for high-volume production lines.

Material Handling: Incorporate features like bag holders, vacuum suction for positioning, or specific material handling mechanisms for unique bag shapes.

Safety Features: Include features like light curtains, heat shields, or emergency stop buttons to prioritize operator safety.

Control Panel: Design a user-friendly control panel with functionalities tailored to your specific sealing process.

Benefits of Using Moosh India's Special Purpose Sealers:

Enhanced Packaging Efficiency: Sealing solutions designed for your specific needs optimize your packaging workflow.

Improved Product Quality: Customized features ensure optimal sealing for your product, safeguarding its integrity and shelf life.

Reduced Waste: Precise sealing minimizes material waste and optimizes resource usage.

Increased Production Capacity: Automation options can significantly increase production output for high-volume operations.

Enhanced Safety Features: Customized safety features prioritize operator well-being.

Streamlined Integration: Our engineers ensure seamless integration with your existing production line.

Why Choose Moosh India's Special Purpose Sealers?

Experience & Expertise: Moosh India has over 15 years of experience in designing and manufacturing custom sealing solutions.

Collaborative Approach: We work closely with you to understand your specific needs and develop a tailored solution.

Quality & Reliability: We use high-grade materials and prioritize quality in every aspect of your custom-built sealer.

Comprehensive Support: Our dedicated team provides pre-sales consultation, project management, installation assistance, and ongoing after-sales support.

Contact Moosh India Today!

Investing in Moosh India's Special Purpose Sealers signifies a commitment to innovative and efficient packaging solutions. Contact Moosh India today to discuss your unique sealing challenges and explore how we can create a custom sealer that perfectly meets your needs!